Chair caning, rush seat weaving, and splint woven seats are all terms for specific designs and techniques used in the process of weaving a chair seat.

This weaving process goes by many names: chair seat weaving, wicker, chair seating, and seatweaving, to name a few.

However, most people lump it all together, including the woven seat pattern and material and the act of weaving itself, so it all becomes “chair caning.”

Actually, the term “chair seat weaving” encompasses many different types of weaving techniques, patterns, designs, and weaving materials. With chair caning itself being only one type of chair seat weaving.

Typically, seats are woven with a variety of pliable materials. Those materials might be; strand cane, cane webbing, rattan reed, paper fibre rush, natural rush, ash, oak or hickory bark splint, Danish Modern cord, Oriental seagrass, and paracord, to name a few.

These materials are then woven on primarily wooden, post and rail frame seats and backs of chairs, rockers, and settees.

Common Chair Seat Weaving Patterns and Designs

Traditional Hand Caning, Hole-to-Hole Cane, Lace Caning

What is “Hole Cane” or “Lace Cane”?

Hole-to-Hole Chair Caning–is the traditional and most well-known of the seat weaving designs and patterns. Hand-caned seats have a lacey, open weave pattern and a row of holes drilled around the perimeter of the seat and/or back.

This age-old chair seat weaving method is woven by hand with individual strands of cane. These strands go through holes that are drilled in the perimeter of the seat, creating the familiar octagon (8-sided), pattern.

Many different gauges of cane are used to suit the design of the chair and size of the drilled holes, but all woven in the same 7-step pattern.

The 7-step method of hand chair caning is tedious and time-consuming to weave, but a lovely, strong, and durable pattern when completed.

Many other designs can be woven through the holes, but this 7-step method has proven to be the most durable and long-lasting.

Please take a look at my Free, Hand Chair Caning Instructions page if you’d like to try your hand at this rewarding craft!

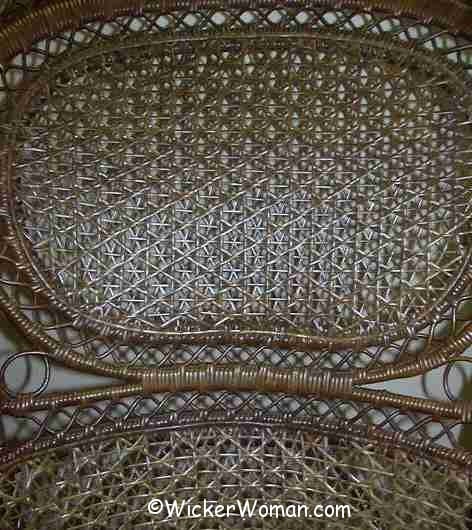

Cane Webbing, Spline, Pressed, Machine Woven, Sheet, or Panel Cane

What is “Cane Webbing” or “Sheet Cane”?

Cane Webbing, Sheet Cane, Pressed Cane–are all names for cane that is prewoven on a loom, forming “sheets” of cane, then “pressed” into a “groove” and held in place with reed “spline” and glue.

This caning technique looks similar to hand caning in the pattern, (and also comes in many variations). But the cane sits in a groove, rather than being woven through a series of holes in the frame.

This loom-woven technique of caning and mechanized groove cutting into the chairs was invented in the 1870s, so has been around for a very long time. And although sometimes thought to be a relatively new process, it is not, and has rivaled the traditional hand chair caning in popularity.

RELATED READING: Free Instructions How to Install Press Cane Webbing

Fancy Cane–Spiderweb, Star of David, Daisy, and Snowflake Cane

What is “Spiderweb Cane” or “Star of David Cane”?

Spiderweb, Star of David, Snowflake and Daisy Cane–are all names of different fancy, intricate, and advanced cane weaving designs.

Since these weaves are not as durable as others, they are usually applied only to the backs of Victorian wicker chairs and rockers, rather than the seats.

All are woven using at least two different gauges of cane to complete the pattern. Best to leave these complex chair caning designs for the experts. They are not for the novice weaver!

Blind Caning, French Caning, Continental Caning

What is “Blind Caning” or “French Caning”?

Blind Caning or French Caning–is woven in the traditional 7-step method design, with regular strand cane, but the holes drilled in the framework do not go all the way through the wood.

Blind Caning is usually reserved for use in the backs or under the arms of chairs rather than in the seats because it’s a delicate weave and not very strong.

Since the holes do not go through the frame, each length of cane must be cut to the exact length needed and fixed in the holes with a plastic peg and a small spot of glue until set.

Only one step can be done at a time, so the glue can set before going on to the next step, making this a very tedious job indeed. Leave this one to the experts!

Porch Cane, Binder Cane, Wide Binding Cane, or Slab Rattan

What is “Porch Cane” or “Wide Binding Cane”?

Porch Cane or Wide Binding Cane–is woven using 4 MM, 5MM, or 6 MM cane, or the larger slab rattan. The pattern can be in a basket weave, diamond, or herringbone twill pattern around the four rungs or dowels that make up the seat.

Sometimes the backs in rockers and chairs are also woven in this pattern with the material to match the seats.

The cane strands look similar to hand cane strands, but these are much wider and woven in a different pattern than traditional hole-to-hole cane.

Splits or Splint Seat Weaving

What are “Splints” or “Splits” Seats?

Splints or Splits–are prepared strips of ash, oak, rattan reed or hickory bark, woven around the seat rungs or dowels of chairs, rockers and settees.

Usually, the pattern is either a herringbone twill or basketweave design to keep it simple. Splints are typically woven using a 3×3 or 4×4 herringbone twill design on the top side with a wider 5×5 twill weave on the bottom.

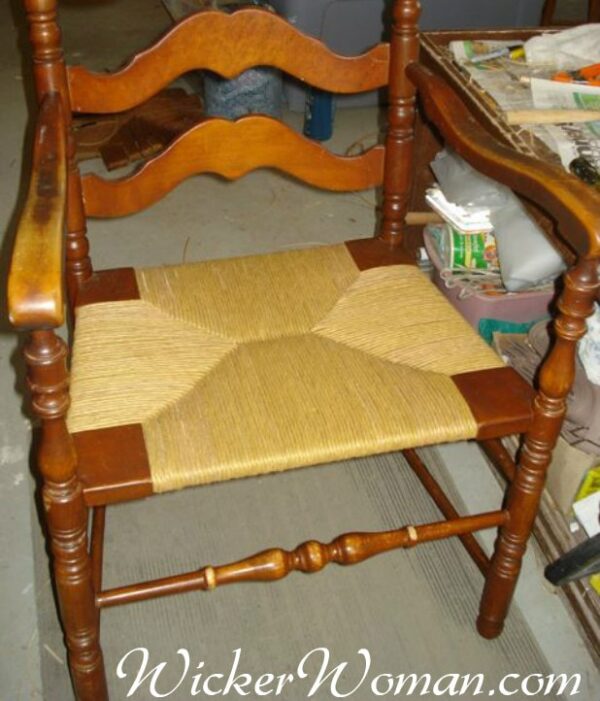

Rush–Hand-twisted and Pre-twisted Natural Rush and Paper Fibre Rush

The rush seatweaving technique uses predominantly either natural cattail leaf rush, bulrush, or man-made paper fibre rush and is woven around the seat rungs.

The weaving forms four distinct triangles in the seat pattern, with the points of the triangles meeting in the center.

What is “Natural Rush”?

There are basically two types of natural rush: one is hand-twisted, and the other is mechanically pre-twisted.

Natural Hand-twisted Rush–is generally reserved for museum pieces or fine old antique chairs and is typically woven with hand-twisted bulrush or cattail leaves for authenticity.

However, because of the degree of difficulty in weaving, the extensive time involved, the cost, and limited availability of materials, hand-twisted natural rush seating is quite expensive.

There are only a handful of weavers across the country that are capable of and willing to weave this type of chair seat anymore.

Can you see the subtle differences between the round bulrush stalks and the flat cattail leaf stalks when you examine the bottoms of the chair seats?

What is “Pre-twisted Natural Rush”?

Pre-twisted Natural Rush or Reel Rush is made up of natural, mechanically twisted, sea-grasses, made to resemble hand-twisted natural cattail leaf rush.

Pre-twisted natural rush (PTNR) is fairly easy to work with compared to hand-twisted rush and is significantly less expensive to have woven and restored.

PTNR is sold by the coil or by the reel. It looks very similar to Oriental seagrass and is frequently confused with seagrass but has a different look to the twist.

Pre-twisted natural rush is smoother and less bumpy than the seagrass strand or rope.

Compare these pictures with those below under the Checkerboard Seagrass heading to see the difference in the twist of the PTNR to the seagrass strands.

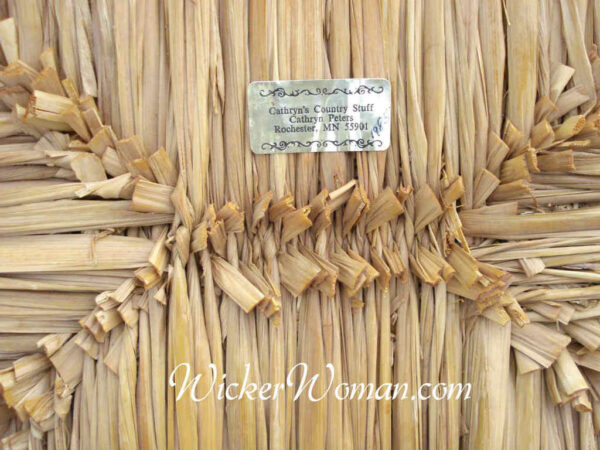

What is “Paper Fibre Rush” or “Paper Rush”?

Paper Fibre Rush is a man-made, single-ply, twisted paper product. It was invented in 1904, for use in weaving chair seats and creating wicker furniture.

Paper rush is cheaper and easier to use than hand-twisted cattail leaves, bulrush or even pre-twisted natural rush (PTNR).

Paper rush is usually used on newer chairs that are not of museum quality or authentic antiques or primitives.

If you want an authentic period-specific woven seat, then it’s best to have a hand-twisted cattail or bulrush seat as the replacement.

Paper fibre rush or paper twist rush comes in a continuous strand, does not require soaking in water, and is very durable, lasting considerably longer than natural rush. Seats woven of paper rush frequently last 50 years or more, depending on the care they receive.

Paper rush is frequently used to weave seats on Colonial style, mule-ear style, and other post and rail modern chair seats, and also was used in weaving wicker furniture from the 1910s-1940s.

Checkerboard Seagrass Seat Weaving or Cording

What is “Checkerboard” Seatweaving?

Checkerboard seats are usually woven with Oriental seagrass, Danish cord, or other types of cording materials in a checkerboard pattern or design.

Both the stool and chair in these photographs were woven in a checkerboard pattern using Oriental seagrass. But of course, many other designs, patterns, and cording materials also could be used to create the same effect.

Lattice or Rustic–Open Seat Weaving

What is “Rustic or Lattice” Seatweaving?

The Rustic or Lattice seatweaving technique uses rawhide strips or sometimes flat reed splints that are woven on chairs, rockers, and couches in a very open weave.

It looks similar to latticework fences or panels and is found frequently on rustic, Adirondack, or cowboy-style furniture, both on seats and backs.

Danish Modern–Cane or Cord Seatweaving

What is “Danish Modern” Cord Seatweaving?

Danish Modern Seatweaving–typically uses a 2-ply laced Danish cord and is looped around “L” shaped nails on the inner framework, woven in a special basket weave design.

Many Danish chair designs also incorporated a cord-woven back as well as the woven seat.

Another material frequently used in weaving Danish Modern chair seats is wide binding cane in either 4, 5 or 6 MM. Cane is woven on both the seat and back, in various patterns but only around the frame and not through drilled holes or put in a groove.

This mid-century Scandinavian furniture was made popular in the 1940s and 1950s by influential designers such as Kaare Klint, Børge Mogensen, Finn Juhl, Arne Jacobsen, and Hans Wegner, just to name a few.

![]()

Well, that pretty well covers the most popular types of chair seatweaving techniques, patterns and materials used. I certainly hope you’ve found this helpful and will Share with your friends and family.

Here’s more chair seat weaving help and information you can use!

Please visit the rest of the site using the navigation links at the top of every page to read more FREE helpful hints and tips about chair seatweaving. Be sure to Bookmark this page so you can come back again often to see what’s new!

If you’d like to reweave the seats of your chairs and need the materials to do so, please visit the suppliers on the National Cane & Basket Supplies Directory™ page, since The Wicker Woman® does not sell supplies to the general public.

Not ready to do your own seatweaving? Need an expert to do the reweaving on your family heirloom or flea market finds? Then take a look at the National Furniture Repair Directory™-Seatweaving section to locate an expert near you through this national directory.

We certainly hope you’ve found this Chair Seat Weaving #101 page informative and helpful today. Please come back again soon to see what changes and additions have been made on WickerWoman.com!

What are your thoughts about this resource article page?

Leave your comments below and share with your social networks!

~~Live Well, Laugh Often, Love Much ~~

Happy Weaving, until next time!

Next –> How-to Care for Cane Furniture

Comments are closed.